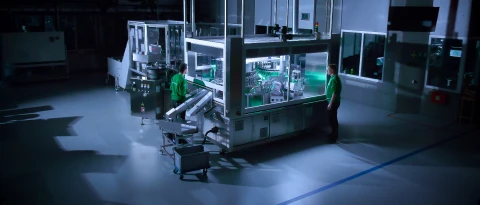

Pad printing machine

For decades, AAE has led the way in pad printing technology, offering innovative solutions that redefine industry standards. Our precision-engineered systems excel in handling diverse materials, products, and shapes, ensuring maximum performance and efficiency.

By seamlessly integrating printing and assembly into a single machine, we help you streamline production, reduce costs, and achieve unmatched ROI. Discover the future of printing with AAE.

What is pad printing?

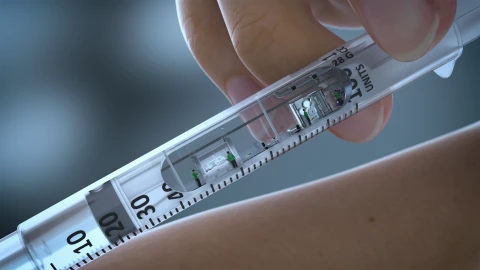

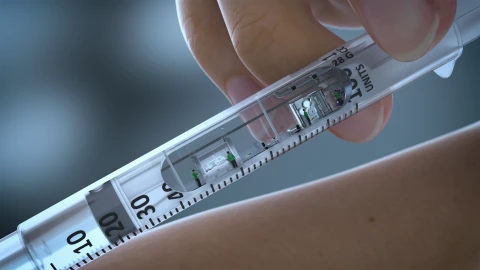

AAE offers accurate, high-precision pad printing solutions for a wide range of plastic products. Our state-of-the-art technology ensures exceptional accuracy, minimizing defects and maximizing product quality. With a rejection rate of less than 0.5%, our machines deliver reliable and efficient performance.

Our systems are designed to handle various plastic materials, including ABS, PE, PC, PP, and more. Whether it's test tubes, cryovials, syringes, writing materials, or other complex shapes, our printing solutions can adapt to your specific needs.

By combining printing and assembly processes into a single, integrated machine, we help you streamline your production line, reduce costs, and optimize your overall operations. Experience the future of printing with AAE.

AAE's expertise in pad printing

We have many examples of pad printing units. For instance our customer presented a complex challenge: to print a small top part of a toy with 8 different colors. The colors needed to match exactly as the customer is extremely critical on the appearance. The temperature of the machine is measured to compensate for any machine expansion during the print process and machine operation. This ensures all colors are printed at the exact same location also when the machine is operated for an extended period of time.

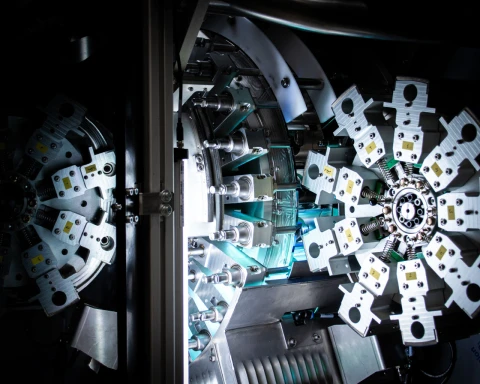

Components of an pad printing machine

AAE’s pad printing machines are built on a foundation of advanced engineering and innovative technology:

- Pre-treatment Techniques: Including Corona, Flame, and Plasma treatments, ensuring optimal ink adhesion to plastics.

- Curing Options: IR, UV Mercury, or UV-LED curing technologies to enhance product durability and aesthetics.

- Laboratory Testing: Our cutting-edge lab tailors processes to your specific material and printing needs.

Every component is designed to ensure seamless integration and efficient operation, delivering superior results with every print.

Advantages of pad printing machines

Pad printing offers numerous benefits that make it a preferred choice for diverse industries:

High-Quality Results: Vibrant colors, sharp details, and consistent accuracy.

Versatility: Suitable for plastics, paper, card stock, and more.

Cost-Effectiveness: Ideal for both small and large production runs.

Eco-Friendly Processes: Modern systems utilize environmentally friendly inks and treatments.

Durability: Long-lasting prints resistant to wear and fading.

Consistency: Precise color matching and image quality across large runs.

These advantages make pad printing a reliable solution for enhancing product quality and production efficiency.

Pad Printing Solutions Tailored to Your Needs

At AAE, we deliver customized pad printing solutions tailored to your specific needs. Whether you require precision for medical components, branding for consumer goods, or complex printing for industrial applications, we have you covered.

Why choose AAE?

Unmatched Precision: Advanced systems for consistent, flawless results.

Versatile Applications: Compatible with various substrates and product shapes.

Efficient Production: Integrated processes for cost-effective manufacturing.

Sustainability: Eco-friendly practices that minimize environmental impact.

Expert Support: A team of professionals with decades of experience.

Let AAE empower your business with cutting-edge pad printing solutions.

Explore our

Customer Cases

FAQ

Absolutely! AAE specializes in creating tailored pad printing solutions that align perfectly with your production needs. Our experienced team collaborates with you to understand your requirements, such as product dimensions, material types, and print designs, to deliver a machine or service uniquely suited to your operation. Whether it’s a complex multi-color application or a high-speed production line, we ensure that our solutions integrate seamlessly into your processes.

To provide an accurate and comprehensive quote, we require the following information:

- Expected Production Volumes: Daily or annual output requirements.

- Operational Details: Hours of operation per day and number of working days per year.

- Product Geometry: Detailed specifications of the product, including dimensions, shapes, and any versions or variations.

- Print Image and Color Scheme: High-resolution design files (e.g., PDF, AI, EPS) and details about the color requirements.

- Timeline: Your desired project completion and delivery dates.

This information helps us design a solution that meets your production, cost, and timeline goals effectively.

Yes, modern pad printing processes are highly eco-friendly. At AAE, we use sustainable practices such as:

- Eco-Friendly Inks: Low-impact, solvent-free, or water-based inks that reduce environmental harm.

- Energy-Efficient Machines: Advanced curing methods like UV-LED, which consume less energy compared to traditional systems.

- Minimal Waste: Efficient ink and material use reduces production waste.

By integrating these practices, pad printing becomes a sustainable choice for industries aiming to reduce their carbon footprint.

How does AAE ensure top-quality results? (H3)

AAE is committed to delivering superior quality in every project. Our quality assurance process includes:

- Precision Engineering: Machines built for high OEE (Overall Equipment Effectiveness) to maximize productivity.

- Advanced Vision Systems: Automated inspections that check for color accuracy, alignment, and defect-free printing.

- Comprehensive Testing: Every machine undergoes rigorous trials to ensure consistent performance under real-world conditions.

- Operator Training: We provide detailed training for your staff to ensure they are proficient in machine operation and maintenance.

- Regular Maintenance Support: Scheduled servicing and easy maintenance routines keep your equipment running efficiently.

AAE offers extensive post-installation support, including:

- Operator Training: Hands-on training sessions to ensure your team can operate the machine confidently and efficiently.

- Service and Maintenance Plans: Customized plans to keep your machines running at peak performance with minimal downtime.

- Technical Support: Our expert technicians are available for troubleshooting, updates, and system upgrades.

- Consumable Supplies: We provide high-quality inks, curing solutions, and replacement parts to support ongoing operations.

Yes, our machines are designed for versatility. They can print on a wide variety of substrates, including plastics (ABS, PE, PC, PP), metals, ceramics, paper, and more. This flexibility makes AAE’s solutions ideal for industries such as medical devices, automotive components, consumer goods, and industrial parts.

By addressing these frequently asked questions, AAE ensures a transparent and collaborative experience, empowering you to achieve optimal results in your pad printing operations.

Ready to transform your production?

With AAE’s inkjet printing machines, you can take your production capabilities to the next level. From improving branding to ensuring product traceability, our solutions are designed to meet your specific needs. Contact AAE today to learn how we can help optimize your production line with our industrial inkjet printers and cutting-edge technology.