Product Life Cycle Management

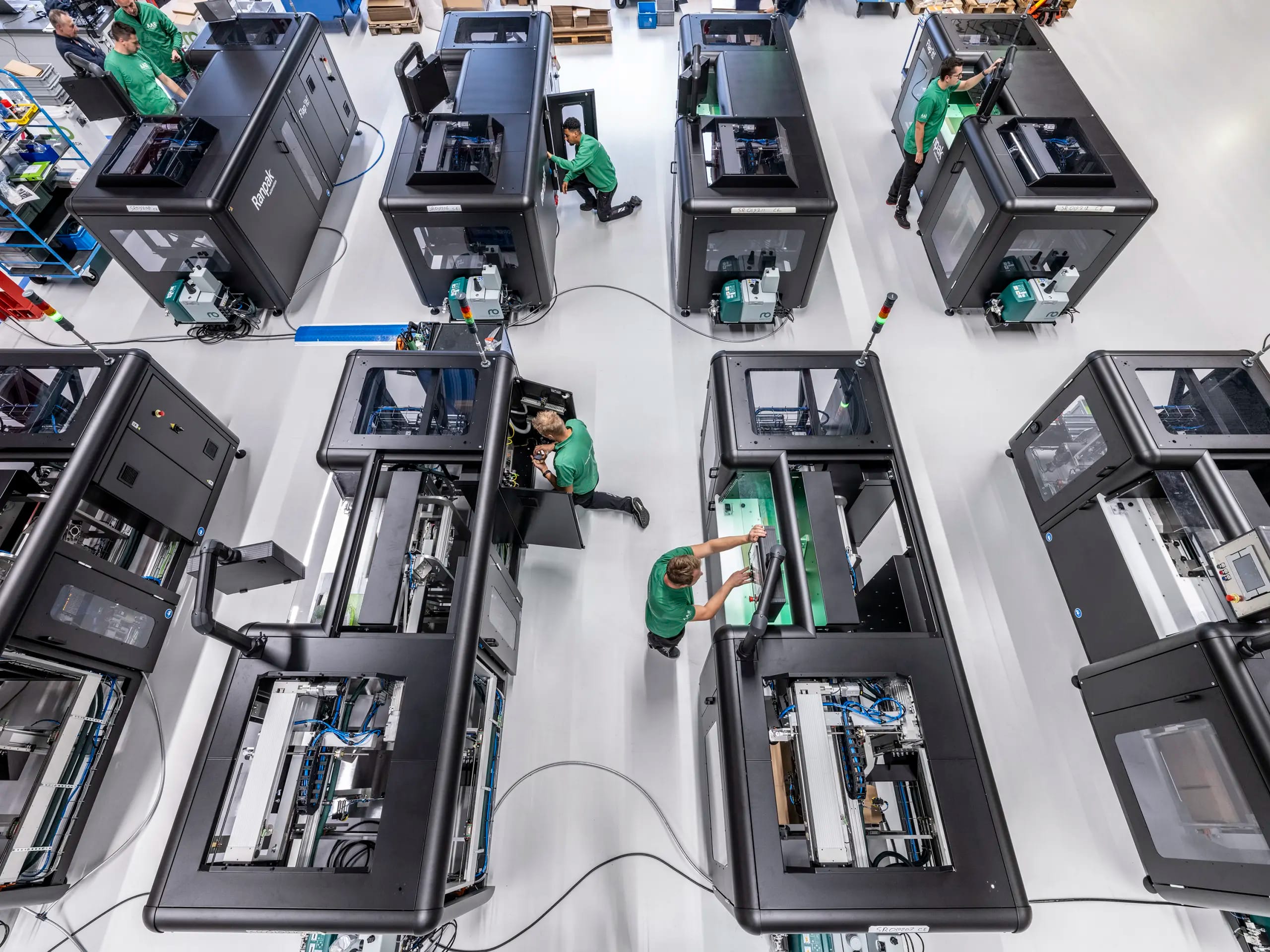

Effective Product Life Cycle Management (PLM) is essential for the low volume, high mix contract manufacturing of high tech manufacturing equipment. PLM streamlines processes, enhances collaboration, and ensures high quality and compliance. It optimizes resources, reduces costs, and provides flexibility to adapt to changing demands. By mitigating risks and supporting innovation, PLM helps maintain a competitive edge and ensures the success of your projects from concept to completion.

At AAE, we leverage our PLM expertise to deliver exceptional manufacturing solutions tailored to your needs.

Supply Chain Management

Effective supply chain management is crucial for the success of any manufacturing project, especially in a high mix, low volume environment. We offer comprehensive supply chain services that optimize inventory levels, reduce waste, and improve resource allocation, leading to cost savings and efficient operations. Our proactive approach involves identifying risks, working capital and developing contingency plans to ensure continuity of supply. This flexibility allows us to quickly adapt to changing demands and market conditions, maintaining a competitive edge.

NPI Trajectories

We organize New Product Introduction (NPI) trajectories to transform customer ideas, concepts or desings, into high-quality, manufacturable products. Our process involves forming dedicated project teams that include project managers, manufacturing engineers, and account managers. We conduct thorough risk analyses, create detailed quotations, and ensure seamless communication between all stakeholders. By focusing on feasibility, industrialization, and continuous improvement, we ensure that each product meets the highest standards from concept to completion.

NPI is where speed meets discipline. We learn fast, lock what works, and carry intent into series without surprises.

Value Engineering

We leverage Value Engineering to enhance the efficiency and cost-effectiveness of our manufacturing processes. By systematically analyzing the functions of systems and components, we identify opportunities to reduce costs without compromising on quality or performance. This approach ensures that we deliver high-value solutions tailored to your specific needs. Our Value Engineering process involves close collaboration with clients to optimize designs, materials, and processes, resulting in improved performance, reliability, and overall value.

Design for Manufacturing

AAE we emphasize the importance of Design for Manufacturing (DFM) to ensure that your products are not only innovative but also practical to produce. Our DFM process starts early in the design phase, where our engineering team collaborates closely with you to identify and mitigate potential manufacturing challenges. This early intervention helps streamline production, reduce costs, and enhance product quality.

By focusing on DFM, we ensure that your designs are optimized for the manufacturing process, leading to fewer revisions and a faster time-to-market. This approach also improves the reliability and scalability of your products, making them more competitive in the market.