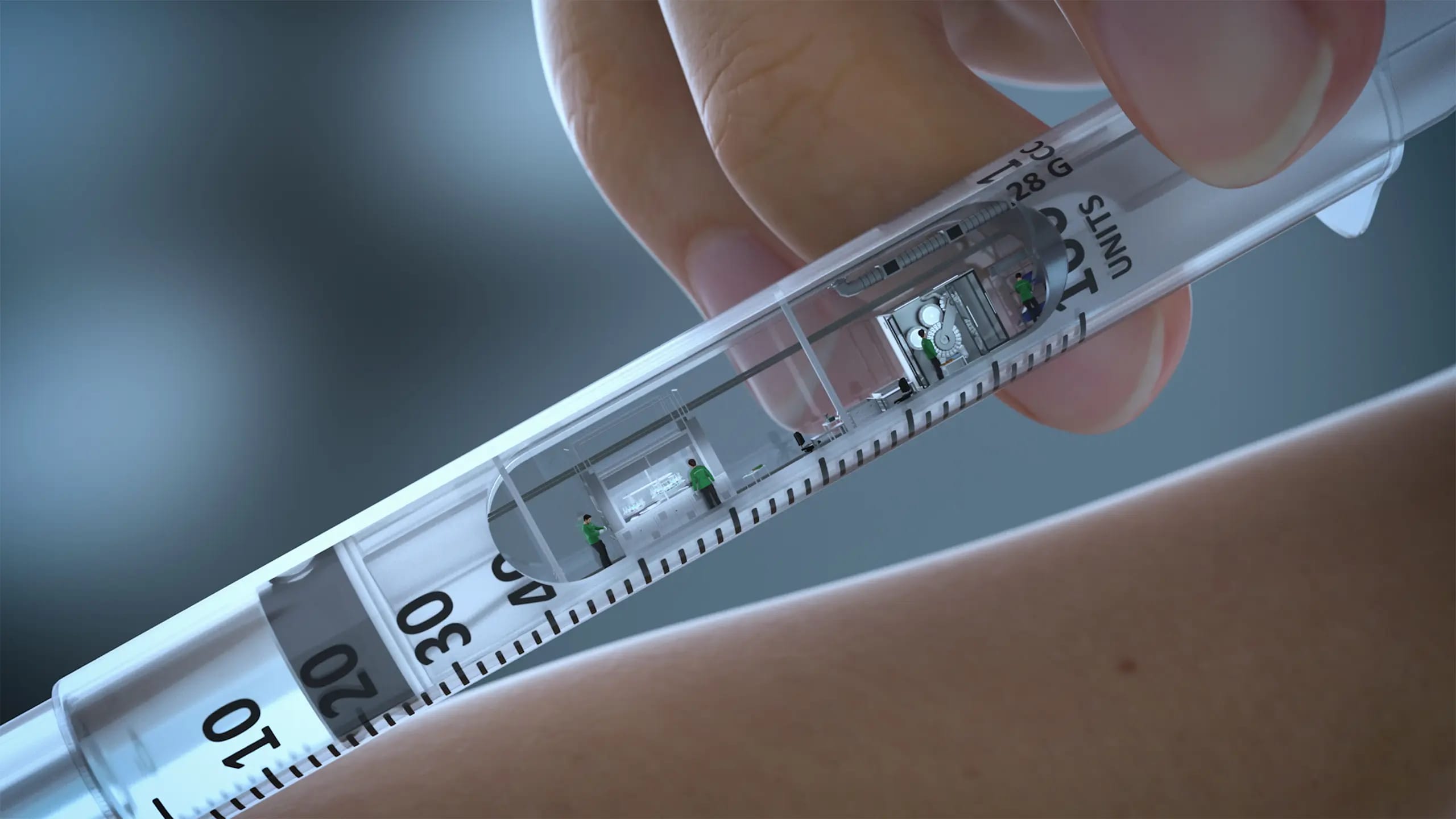

Pen Injector Assembly Line

At AAE, we specialize in delivering advanced automation solutions for pen injector assembly lines, designed to meet the high demands of the medical and pharmaceutical industries. Our systems ensure the precise and efficient assembly of pen injectors used for delivering critical medications such as insulin, hormones, and biologics. With a focus on accuracy and reliability, AAE’s assembly lines not only meet stringent regulatory standards but also optimize production efficiency, scalability, and cost-effectiveness.

What is a pen injector assembly line?

A pen injector assembly line is an automated system engineered to assemble medical pen injectors that allow patients to administer medications with ease, accuracy, and safety. These systems are critical for producing devices used in diabetes care, hormone therapies, and other medical treatments requiring self-injection. AAE’s lines are designed for high precision, ensuring each injector is assembled to meet exacting medical standards.

Benefits of an efficient assembly line

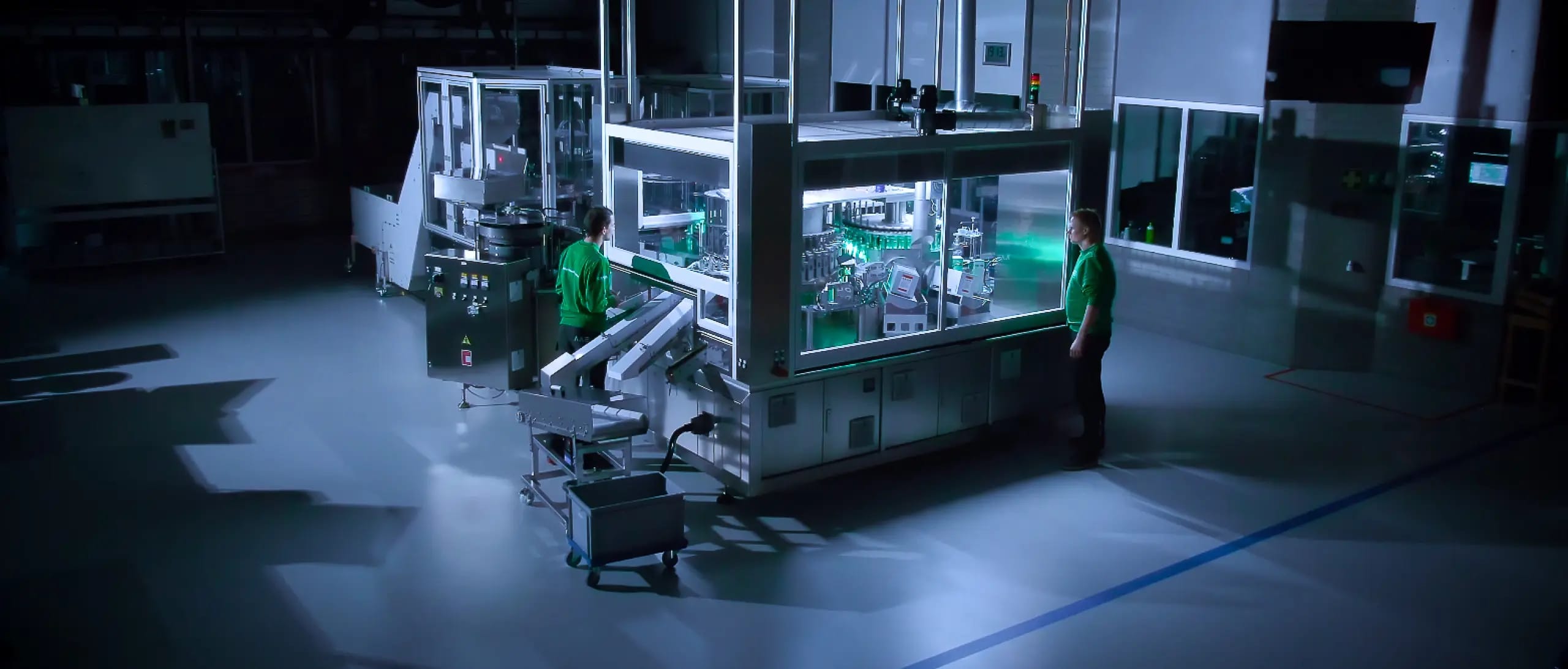

An efficient pen injector assembly line brings numerous advantages to manufacturers. Automation significantly enhances production speed, enabling the rapid assembly of high-quality injectors with minimal errors. By reducing defects and ensuring consistency, these lines drive higher product reliability while cutting labor costs and material waste. Furthermore, AAE’s scalable systems are built to grow alongside your production needs, ensuring adaptability to future demands.

Key components of a pen injector assembly line

The pen injector assembly line is composed of several critical components that work together to ensure flawless production:

Component feeders: Deliver individual parts like needles, barrels, and casings to the assembly stations.

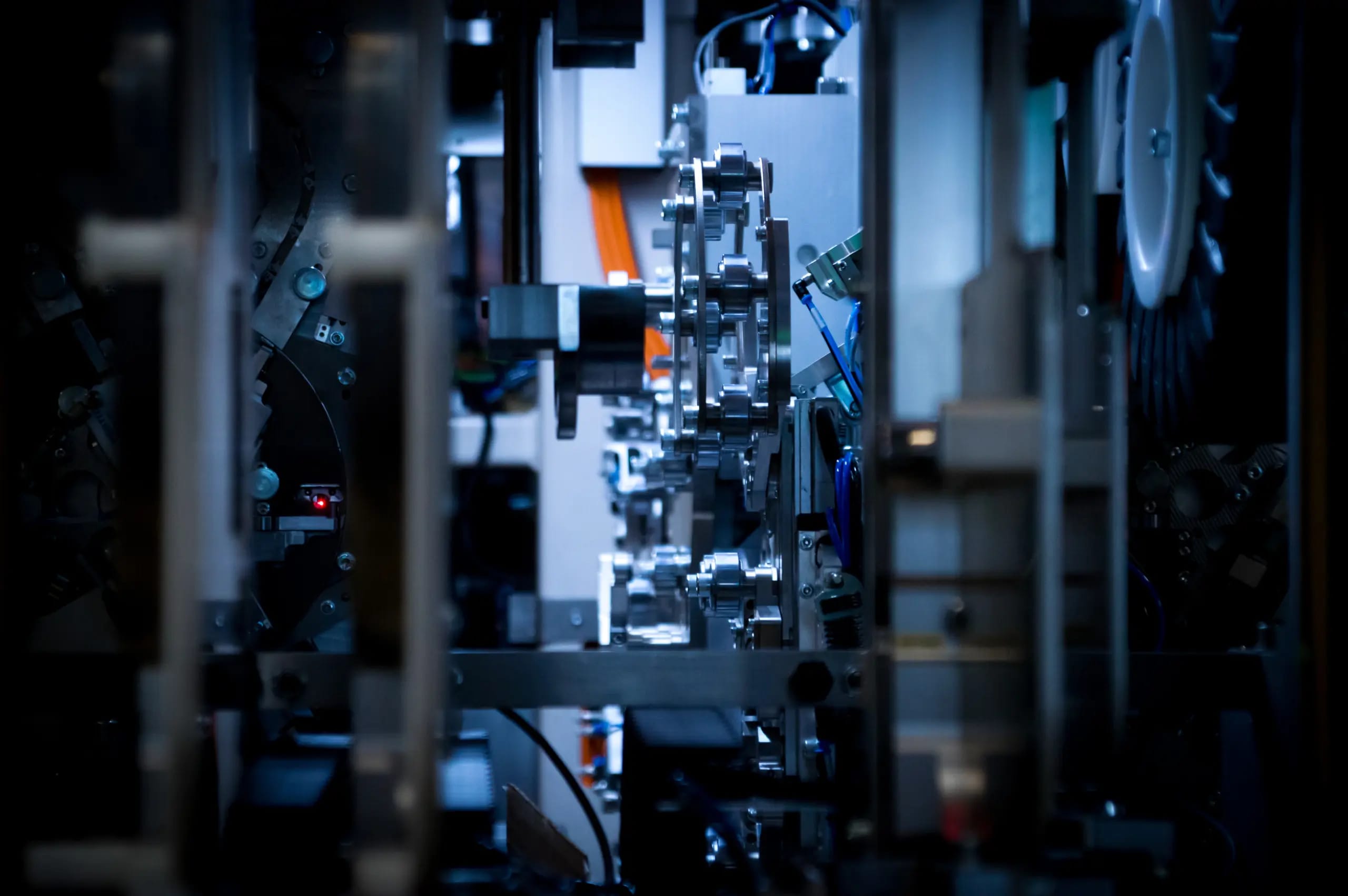

Automated assembly stations: Precisely fit and assemble each component, ensuring tight tolerances and high product integrity.

Vision inspection systems: Check for correct alignment and assembly, ensuring each product meets quality standards.

Testing stations: Validate the functionality and dosage accuracy of every pen injector produced.

Packaging systems: Automatically prepare finished products for labeling, packaging, and shipment.

Steps in the pen injector assembly process

The assembly process follows a clear, structured workflow to ensure precision and efficiency. First, components like injector bodies, needles, and cartridges are fed into the system. Then, the automated stations perform precise assembly, combining these parts into a fully functional pen injector. After assembly, the product undergoes inspection and testing to verify accuracy and safety. Once approved, the injectors are labeled, packaged, and prepared for distribution.

Applications and medical industries

Pen injectors play an essential role in modern healthcare. They are most commonly used for insulin delivery, allowing patients to manage diabetes with ease. Pen injectors are also utilized in hormone replacement therapies, such as growth hormone treatments, and for the administration of biologic drugs in chronic conditions. Emergency-use injectors, such as epinephrine pens, are another critical application, ensuring timely treatment in life-threatening situations.

FAQ

Why AAE?

At Advanced Automated Equipment (AAE), we specialize in the complexities of disposable

syringe assembly machines and drug delivery device assembly. Our solutions are crafted to tackle the key challenges in this critical sector. Leveraging advanced technologies, our engineering team

expertly handles the delicate assembly process, ensuring material compatibility and

minimizing risks of damage or contamination. With a strong emphasis on cleanroom

environments, our machines are designed with advanced filtration and controlled airflow

systems to maintain the highest standards of cleanliness and safety.

Our employees are driven by the dream to make our world a better and happier place. Together with our customers, we make this dream come true.